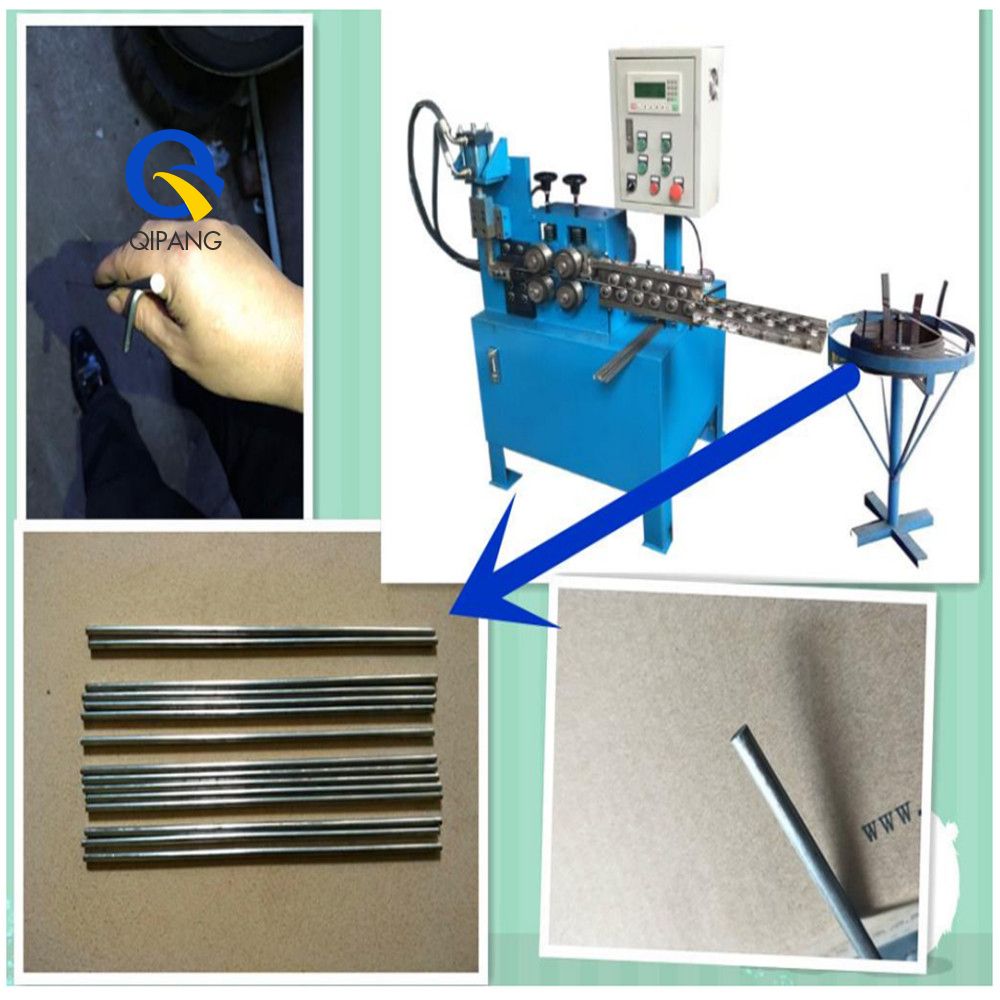

QIPANG hydraulic straightening and cutting machine suitable for 1mm,6mm wire straightened and cutter

Parameter:

1. Applicable wire diameter :

1.0-6.0mm

11. The cutting length is adjustable and is controlled by PLC program.

The operating instructions:

1.Before the machine works, it is necessary to inject about three-quarters of the hydraulic oil into the hydraulic tank (the hydraulic oil will overflow when the machine is too full), and at the same time, inject oil into the oil hole to lubricate all parts.

2. Connect the power supply (380V, 5 wires, 3 live wire, black is the neutral line, the two colors wire are the ground line), turn on the power switch, the display will light, see if the direction of the motor is going forward, click on the jog whether the switch machine is working properly.

3. The screen shows the length of the wire (is the length of your product), other data has been debugged before leaving the factory. Please do not arbitrarily change, first press [SET], there will be a black block, then you can adjust the data, [ENT] is the confirmation button, [ALM] is the output is cleared.

4. The iron wire passes through the 2 sets of straightening wheels from the wire frame all the way to the incision. Press the screw, press the hoe, press the jog feed line, and press the jog switch to straighten the cut and connect. Then open the automatic switch and you can work continuously.

Equipment maintenance :

1. Check each screw tightly every day, add lubricant to each turn, and turn it on again.

2. Generally, do not disassemble parts during routine maintenance. When disassembling, it should be carried out by a special repair worker. If abnormal phenomena are found during operation of the equipment, it should be stopped immediately, and it is not allowed to operate with disease.

3. Regularly check whether the screws and fastening parts of each part are locked. Do not allow looseness. Check whether the power cord is aging or not. The socket contact is good and reliable, and repair and replace it in time.

4. If it has not been used for a long time, it should be cleaned first and kept safely. It should be fully lubricated once every six months and idling for a short time.

5. Equipment accessories and special tools should have special cabinet racks to keep clean and prevent rust and bumps.

Shanghai Qipang Industrial Co.,LTD.are specialized in producing wire straighteners. We are two companies in qipang group, one is Shanghai Qipang Industrial Co.,LTD. which has a superior geographical location. Its head office is located in Shanghai, which is connected with Shanghai port.The factory is located in kunshan city, Kunshan Qipang Mechanical and Electrical Equipment Co.,LTD. which is the junction of jiangsu province and Shanghai city, with convenient transportation and advanced technology.The company has a wealth of enterprise resources, excellent corporate culture, strong corporate philosophy, to serve customers for the purpose, committed to creating a leading brand in the industry, and the domestic brand to the world, is one of the outstanding representatives of the rapid economic development of the 21st century.

We have been producing straighteners for ten years.We are the best in our field.We mainly have wire straightener roller,feeding straightener, PLC control,straightener and cutting machine ,pipe bender , necking machine and so on. Straightener suitable for wire and pipe with diameters ranging from 0.05mm to 30MM.

The straightener can also be customized according to the buyer's requirements. Our products are of high quality and low price, and have good after-sale service.We will provide video teaching installation and adjustment, so you don't have to worry about buying it and not using it. Our partners include the United States, Canada, Russia, Vietnam, Thailand, Poland, and many other countries.Choose us you won't .